1. Mwachidule

Chubu chamkati ndi chinthu chochepa kwambiri cha mphira, ndipo zonyansa zina zimapangidwa mosalephera panthawi yopanga, zomwe sizingafanane ndi tayala lakunja, komamavavuali osalimba, ndipo mavavuwa amatha kusinthidwanso ndikugwiritsidwanso ntchito popanga machubu amkati. Kampani yathu yachita zoyeserera pakubwezeretsanso ndikugwiritsanso ntchito mavavu amkati, koma mawonekedwe a ma valve obwezerezedwanso ndi otsika, ndipo mphamvu yolumikizirana pakati pa valavu ndi mphira ya mphira ndiyotsika, ndipo iyenera kugwiritsidwanso ntchito isanayambe kugwiritsidwa ntchito. .

Ntchitoyi imathandizira njira yobwezeretsanso zinyalala ndi mavavu opanda machubu amkati kuti achepetse zinyalala ndikukweza phindu lazachuma lamakampani.

2. Kusanthula Vuto

Njira yobwezeretsanso zinyalala zoyambilira ndi zolakwikamavavu amkatindi motere: zinyalala ndi zolakwika mavavu a mkati mwa chubu → kutentha → chithandizo cha asidi → vulcanization yamtundu umodzi (zomatira zomatira) → bristles pamapadi a rabala.

Mavuto a ndondomeko yomwe tatchulayi ndi awa.

(1) Kutentha kwa zinyalala ndi mavavu opanda machubu amkati kungayambitse kuwononga chilengedwe. Thupi la vavu yobwezerezedwanso limapunduka mosavuta ndipo limakhala ndi mawonekedwe akuda. Ndizovuta kuyeretsa panthawi ya chithandizo cha asidi, ndipo ndizosavuta kuwononga njira zina.

(2) Pofuna kuthandizira kuchotsa ndi kuchotsa valavu, mapangidwe oyambirira a nkhungu ya vulcanization ndi nkhungu imodzi ndipo imagawidwa mu magawo atatu. Single-mode vulcanization imatenga nthawi yayitali, kutsika kwachangu, kulimbikira kwambiri kwa ntchito komanso kugwiritsa ntchito mphamvu, ndipo kunja kwa valavu yovunda kumakonda kukhala ndi mikwingwirima yambiri, mphira imakutira pakamwa pakamwa, ndipo mawonekedwe a valavu samakwaniritsa zofunikira. Mphamvu zomatira za pad zomatira nazonso sizikhazikika.

(3) Buku la bristling la rabara la pad lili ndi zovuta za kulimbikira kwa ntchito, kutsika pang'ono, komanso kusasunthika kosagwirizana, komwe kumakhudza kugwirizana kwa mphira ndi mphira wamkati wa chubu.

3 Kupititsa patsogolo zotsatira

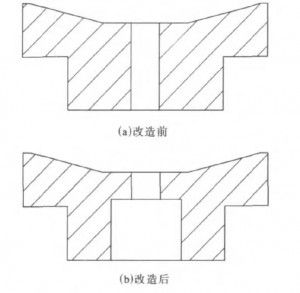

Chithunzi 2 chikuwonetsa thupi la nozzle lomwe lidachira pambuyo komanso pambuyo pakuwongolera njira yotsata. Zitha kuwoneka kuchokera pa Chithunzi 2 kuti thupi la mphuno lomwe limathandizidwa ndi njira yowongoleredwa mwachiwonekere ndi loyera, ndipo thupi lamphuno limakhala losalala. Ndi njira yabwino, kuchuluka kwa asidi ndi madzi omwe amagwiritsidwa ntchito ndi ochepa, ndipo kuwonongeka kwa chilengedwe kumakhala kochepa, ndipo mphira wodulidwa ukhoza kubwezeretsedwanso kuti apange mphira wobwezeretsedwa.

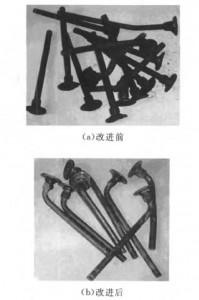

Pamaso pa kusintha, kutentha kutengerapo zotsatira za nkhungu ndi osauka, ndi vulcanization amatenga 15 mphindi. Malingana ndi momwe ntchito yogwiritsira ntchito vulcanizer ilipo, ma valve 4 okha amatha kugwedezeka panthawi imodzi, ndipo pafupifupi ma valve 16 amatha kupangidwa pa ola limodzi, zomwe siziphatikizapo kuyika nkhungu. nthawi. Ndi nkhungu yosinthidwa yophatikizidwa, zimangotenga mphindi 5 kuti ziwonongeke, ma valve 25 amatha kugwedezeka nthawi iliyonse, ndipo ma valve a 300 akhoza kupangidwa pa ola limodzi. Ndiosavuta kuyika ndikutsitsa, ndipo kuchulukira kwa ntchito kumakhala kochepa.

Ndi makina osinthidwa ndi makina ochotsera, ma valve onse owongoka ndi ma valve okhotakhota amatha kupangidwa, ndipo ndondomekoyi ndi yofanana. Palibe kusiyana koonekeratu kwa maonekedwe ndi khalidwe lamkati pakati pa ma valve obwezeretsedwa ndikugwiritsidwanso ntchito ndi njira yabwino komanso ma valve atsopano. Zotsatira zoyesa zikuwonetsa kuti mphamvu yolumikizana pakati pa valavu ndi mphira ya mphira yosinthidwanso ndi njira yabwino ndi 12.8 kN m-1, pomwe mphamvu yolumikizana pakati pa valavu yatsopano ndi mphira ya mphira ndi 12.9 kN m-1, Miyezo yamabizinesi imafuna kuti mphamvu zomangira sizichepera 7 kN · m-1.

Pambuyo pazaka zopitilira khumi zachitukuko chofulumira, makampani opanga ma valve ku China adalamulira dziko lonse lapansi. Pakalipano, kupanga ma valve kudziko langa kumapanga zoposa 70% za dziko lonse lapansi kupanga mavavu, ndikuyika patsogolo pa kupanga ndi kugulitsa ma valve padziko lapansi. Pofuna kukwaniritsa zosowa za misika yapakhomo ndi yapadziko lonse, kuchuluka kwa ma tubeless ma valves kwawonjezeka pang'onopang'ono. Mu 2015, kutuluka kwa ma valve opanda ma tubes kwakhala ndi theka la kuchuluka kwa ma valve. Kufunika kwakukulu kwa msika wapakhomo nthawi zonse kumalimbikitsa chitukuko cha makampani.

Kufuna kwa msika wa vavu kumagawika makamaka pamsika wa OEM ndi msika wa AM. Zomwe zaposachedwa zikuwonetsa kuti valavu ya mpweya ndi gawo lofunikira lachitetezo cha module yama wheel wheel. Chifukwa chakhala chikuwonekera kunja kwa nthawi yayitali, chiyenera kupirira kukokoloka koopsa kwa chilengedwe. Mavavu nthawi zambiri amasinthidwa pakayendera pachaka ndikuyika matayala m'malo, kotero kufunikira kwa mavavu pamsika wa AM ndikokwera kwambiri kuposa komwe kuli pamsika wa OEM.

4. Epilogue

Ndi ukadaulo wotsogola, bola ngati thupi la valve silimapunduka, limatha kubwezeretsedwanso. Ubwino wa mavavu obwezerezedwanso amakwaniritsa zofunikira zogwiritsidwa ntchito, zomwe zimatha kuchepetsa kugwiritsa ntchito zida ndi mphamvu, kuchepetsa mtengo wopangira machubu amkati, ndikuwongolera phindu lazachuma lamakampani.

Nthawi yotumiza: Dec-02-2022