1. Theoretical Test and Analysis

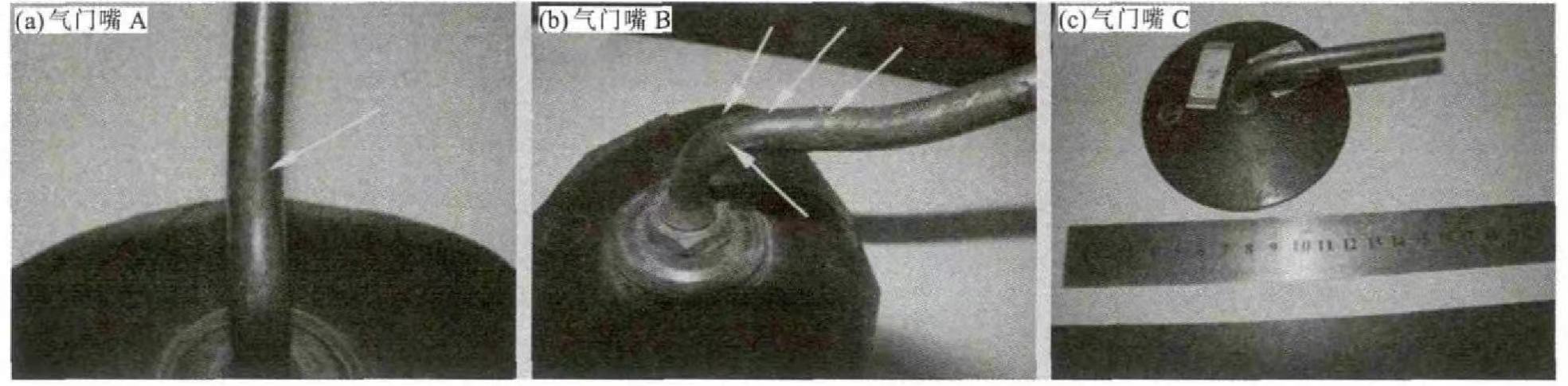

mwa 3valavu matayalazitsanzo zoperekedwa ndi kampaniyo, 2 ndi ma valve, ndipo 1 ndi valve yomwe sinagwiritsidwe ntchito pano.Kwa A ndi B, valavu yomwe sinagwiritsidwe ntchito imalembedwa kuti imvi.Chithunzi Chokwanira 1. Kunja kwa valavu A kumakhala kozama, pamwamba pa valavu B ndi pamwamba, pamwamba pa valavu C ndi pamwamba, ndipo pamwamba pa valavu C ndi pamwamba.Mavavu A ndi B amaphimbidwa ndi zinthu zowonongeka.Vavu A ndi B imasweka pamapindikira, mbali yakunja ya bend ili pambali pa valavu, pakamwa pamlomo wa valve B imasweka kumapeto, ndipo muvi woyera pakati pa malo osweka pamwamba pa valve A amalembedwa. .Kuchokera pamwamba, ming'alu ili paliponse, ming'alu ndi yaikulu, ndipo ming'alu ili paliponse.

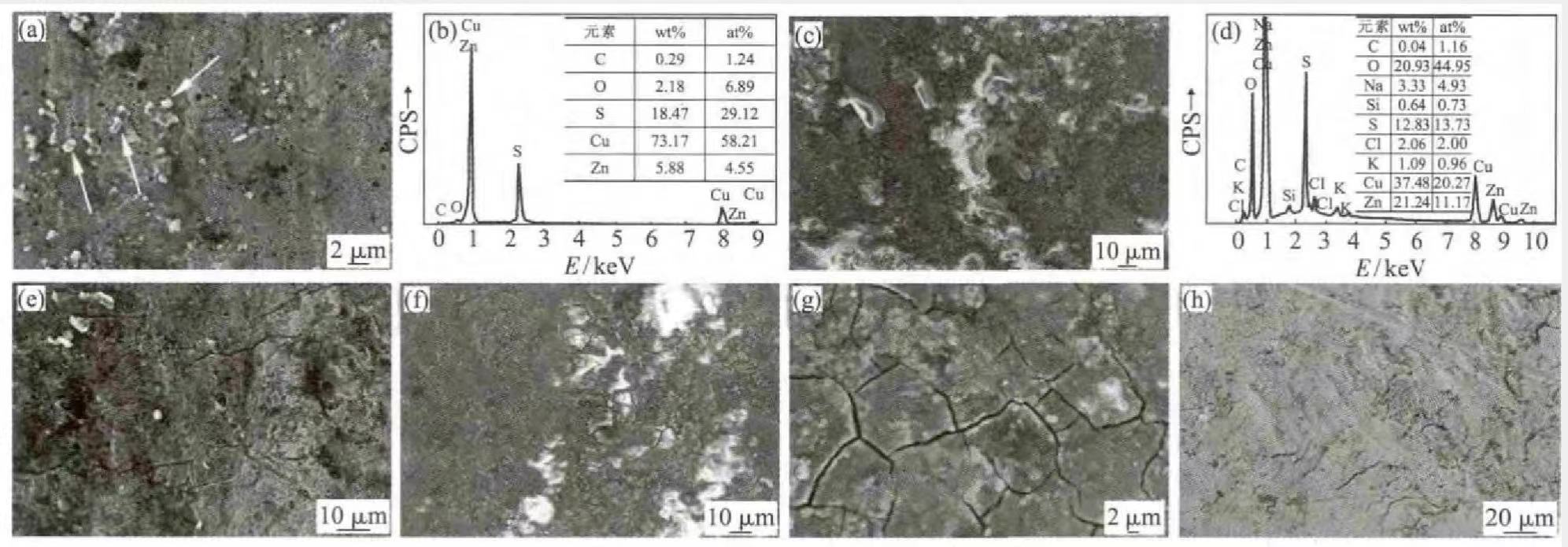

Chigawo chavalavu ya tayalaZitsanzo za A, B, ndi C zidadulidwa kuchokera kupindika, ndipo mawonekedwe apamwamba adawonedwa ndi ZEISS-SUPRA55 yowunikira ma microscope yamagetsi, ndipo mawonekedwe ang'onoang'ono adawunikidwa ndi EDS.Chithunzi 2 (a) chikuwonetsa microstructure ya valve B pamwamba.Zitha kuwoneka kuti pali mitundu yambiri yoyera ndi yowala pamtunda (yomwe imasonyezedwa ndi mivi yoyera pachithunzichi), ndipo kusanthula kwa EDS kwa tinthu tating'onoting'ono koyera kumakhala ndi chiwerengero chachikulu cha S. Zotsatira za kusanthula kwamphamvu kwazitsulo zoyera. zikuwonetsedwa mu Chithunzi 2 (b).

Zithunzi 2 (c) ndi (e) ndi ma microstructures apamwamba a valve B. Tingaone kuchokera pa Chithunzi 2 (c) kuti pamwamba pamakhala pafupi ndi zinthu zowonongeka, ndi zowonongeka zazinthu zowonongeka ndi mphamvu zowonongeka. makamaka amaphatikizapo S, Cl ndi O, zomwe zili mu S m'maudindo apadera ndi apamwamba, ndipo zotsatira zowunikira mphamvu zowonongeka zikuwonetsedwa mu Chithunzi 2 (d).Zitha kuwoneka kuchokera ku Chithunzi 2 (e) kuti pali ming'alu yaying'ono pamphepete mwa valve pamwamba pa valve A. Zithunzi 2 (f) ndi (g) ndi micromorphologies pamwamba pa valavu C, pamwamba ndi zophimbidwa kwathunthu ndi dzimbiri, ndipo zinthu zowononga zimaphatikizanso S, Cl ndi O, zofanana ndi Chithunzi 2(e).Chifukwa chosweka chikhoza kukhala kupsinjika kwa corrosion cracking (SCC) kuchokera pakuwunika kwazinthu zowonongeka pamtunda wa valve.Chithunzi 2 (h) imakhalanso pamwamba pa microstructure ya valve C. Zitha kuwoneka kuti pamwamba pake ndi yoyera, ndipo mankhwala omwe ali pamwamba omwe amafufuzidwa ndi EDS ndi ofanana ndi alloy yamkuwa, kusonyeza kuti valavu ndi osati dzimbiri.Poyerekeza mawonekedwe a microscopic morphology ndi mankhwala a ma valve atatu, akuwonetsedwa kuti pali zowononga zowonongeka monga S, O ndi Cl m'madera ozungulira.

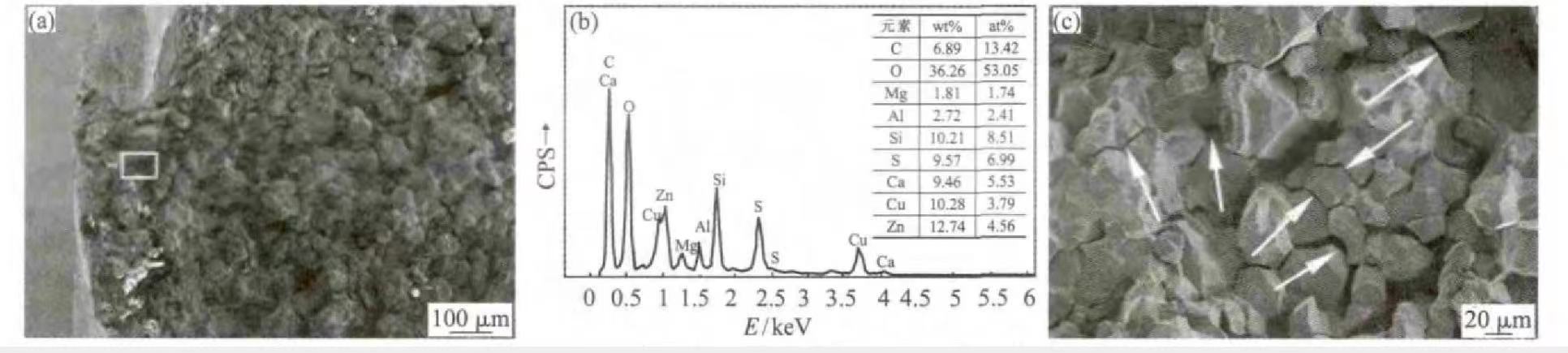

Kuphulika kwa valve B kunatsegulidwa kupyolera mu kuyesa kupindika, ndipo kunapezeka kuti mng'aluwo sunalowetse gawo lonse la valavu, losweka pambali ya backbend, ndipo silinaphwanyike kumbali yotsutsana ndi backbend. wa valavu.Kuyang'ana kowonekera kwa fracture kumasonyeza kuti mtundu wa fracture ndi mdima, kusonyeza kuti fracture yawonongeka, ndipo mbali zina za fracture zimakhala ndi mtundu wakuda, zomwe zimasonyeza kuti zowonongeka zimakhala zovuta kwambiri m'maderawa.Kuphulika kwa valavu B kunawonedwa pansi pa microscope ya electron, monga momwe tawonetsera pa Chithunzi 3. Chithunzi 3 (a) chikuwonetsa maonekedwe a macroscopic a kuphulika kwa valve B.Zitha kuwoneka kuti fracture yakunja pafupi ndi valve yaphimbidwa ndi zinthu zowonongeka, zomwe zimasonyezanso kukhalapo kwa zofalitsa zowonongeka m'madera ozungulira.Malingana ndi kusanthula kwa mphamvu zamagetsi, zigawo za mankhwala a mankhwala owononga kwambiri ndi S, Cl ndi O, ndipo zomwe zili mu S ndi O ndizokwera kwambiri, monga momwe tawonetsera mkuyu 3 (b).Poyang'ana pamwamba pa fracture, amapezeka kuti kukula kwa mng'alu kumakhala pamtundu wa kristalo.Chiwerengero chachikulu cha ming'alu yachiwiri chikhoza kuwonedwanso poyang'ana fracture pa magnification apamwamba, monga momwe tawonetsera pa Chithunzi 3 (c).Ming'alu yachiwiri imalembedwa ndi mivi yoyera pachithunzichi.Zopangira dzimbiri komanso mawonekedwe akukula kwa ming'alu pamalo osweka akuwonetsanso mawonekedwe a kupsinjika kwa dzimbiri.

Kuphulika kwa valve A sikunatsegulidwe, chotsani gawo la valve (kuphatikizapo malo osweka), pezani ndi kupukuta gawo la axial la valve, ndipo gwiritsani ntchito Fe Cl3 (5 g) + HCl (50 mL) + C2H5OH ( 100 mL) yankho linakhazikika, ndipo kapangidwe kazitsulo ndi kakulidwe ka ming'alu kakuwoneka ndi microscope ya Zeiss Axio Observer A1m.Chithunzi 4 (a) chikuwonetsa mawonekedwe a metallographic a valve, omwe ali α + β awiri-gawo, ndipo β ndi yabwino komanso granular ndipo imagawidwa pa α-phase matrix.Njira zofalitsa ming'alu pa ming'alu yozungulira zikuwonetsedwa mu Chithunzi 4 (a), (b).Popeza kuti malo ong’alukawo amadzazidwa ndi zinthu za dzimbiri, kusiyana pakati pa ming’alu iwiriyo n’kokula, ndipo n’kovuta kusiyanitsa njira zofalitsira ming’alu.chodabwitsa cha bifurcation.Mikwingwirima yambiri yachiwiri (yomwe ili ndi mivi yoyera pachithunzichi) inawonedwanso pa mng'alu woyambirira uwu, onani Mkuyu 4 (c), ndipo ming'alu yachiwiriyi inafalikira pamodzi ndi tirigu.Zitsanzo za valve etched zidawonedwa ndi SEM, ndipo zidapezeka kuti panali ming'alu yaying'ono m'malo ena ofanana ndi ming'alu yayikulu.Ming'alu yaying'ono iyi idachokera kumtunda ndikufalikira mpaka mkati mwa valavu.Ming’aluyo inali ndi ming’alu iwiri ndipo inafalikira m’mbali mwa njerezo, onani Chithunzi 4 (c), (d).Chilengedwe ndi kupsinjika kwa ma microcracks amenewa ndi pafupifupi ofanana ndi a mng'alu waukulu, kotero zikhoza kuganiziridwa kuti mawonekedwe a kufalikira kwa mng'alu waukulu ndi intergranular, zomwe zimatsimikiziridwa ndi kuphulika kwa valavu B. The bifurcation phenomenon of mng'alu akuwonetsanso mawonekedwe a kupsinjika kwa dzimbiri kusweka kwa valavu.

2. Kusanthula ndi Kukambitsirana

Kufotokozera mwachidule, zikhoza kuganiziridwa kuti kuwonongeka kwa valavu kumayambitsidwa ndi kupsinjika kwa corrosion kusweka chifukwa cha SO2.Kupsinjika kwa dzimbiri kung'ambika nthawi zambiri kumafunika kukwaniritsa zinthu zitatu: (1) zinthu zomwe zimakhudzidwa ndi dzimbiri;(2) zowononga sing'anga tcheru ku kazitsulo zamkuwa;(3) mikhalidwe ina ya kupsinjika maganizo.

Amakhulupirira kuti zitsulo zoyera sizikhala ndi dzimbiri, ndipo ma alloys onse amatha kupsinjika ndi dzimbiri mosiyanasiyana.Kwa zida zamkuwa, nthawi zambiri amakhulupirira kuti mawonekedwe a magawo awiri amakhala ndi kupsinjika kwakukulu kwa dzimbiri kuposa mawonekedwe a gawo limodzi.Zanenedwa m'mabuku kuti pamene Zn zomwe zili muzitsulo zamkuwa zimaposa 20%, zimakhala ndi zovuta zowonongeka zowonongeka, ndipo kukweza kwa Zn, kumapangitsa kuti kupsinjika maganizo kuwonongeke.Mapangidwe a metallographic a mpweya wa mpweya pankhaniyi ndi α + β wapawiri-gawo aloyi, ndipo Zn zili pafupifupi 35%, kupitilira 20%, kotero zimakhala ndi kupsinjika kwakukulu kwa dzimbiri ndipo zimakwaniritsa zofunikira pakupsinjika. kuwonongeka kwa dzimbiri.

Pazida zamkuwa, ngati kuwongolera kupsinjika sikunachitike pambuyo pa kuzizira kozizira, dzimbiri la nkhawa limachitika pansi pamikhalidwe yoyenera komanso malo owononga.Kupsinjika komwe kumayambitsa kupsinjika kwa dzimbiri nthawi zambiri kumakhala kupsinjika kwanthawi yayitali, komwe kungagwiritsidwe ntchito kupsinjika kapena kupsinjika kotsalira.Tayala lagalimoto litawonjezedwa, kupsinjika kwamphamvu kumapangidwa motsatira njira ya axial ya mphuno ya mpweya chifukwa cha kuthamanga kwambiri kwa tayala, zomwe zingayambitse ming'alu yozungulira mumphuno ya mpweya.Kupsyinjika kwamphamvu komwe kumachitika chifukwa cha kuthamanga kwa mkati mwa tayala kungawerengedwe molingana ndi σ = p R/2t (pomwe p ndi mphamvu yamkati ya tayala, R ndi m'mimba mwake mkati mwa valavu, ndipo t ndi makulidwe a khoma la valavu).Komabe, kawirikawiri, kupanikizika kwapakati pa tayala sikuli kwakukulu, ndipo zotsatira za kupsinjika kotsalira ziyenera kuganiziridwa.Malo osweka a ma nozzles a gasi onse ali kumbuyo, ndipo zikuwonekeratu kuti kupunduka kotsalira kumbuyoko ndi kwakukulu, ndipo pali kupsinjika kotsalira komweko.Ndipotu, m'zigawo zambiri zazitsulo zamkuwa, kuwonongeka kwa corrosion sikumayambika kawirikawiri chifukwa cha kupanikizika kwa mapangidwe, ndipo zambiri zimayambitsidwa ndi zotsalira zotsalira zomwe sizikuwoneka ndi kunyalanyazidwa.Pankhaniyi, kumbuyo kumbuyo kwa valavu, mayendedwe a kupsinjika kwamphamvu komwe kumapangidwa ndi kukakamiza kwamkati kwa tayala kumagwirizana ndi momwe kupanikizika kotsalirako kumakhalira, ndipo kuwongolera kwa zovuta ziwirizi kumapereka kupsinjika kwa SCC. .

3. Mapeto ndi Malingaliro

Pomaliza:

Kuphulika kwavalavu ya tayalamakamaka chifukwa cha nkhawa dzimbiri ang'onoang'ono chifukwa SO2.

Malingaliro

(1) Tsatirani gwero la malo owononga malo ozunguliravalavu ya tayala, ndipo yesetsani kupewa kukhudzana mwachindunji ndi sing'anga zowononga zozungulira.Mwachitsanzo, chophimba cha anti-corrosion chingagwiritsidwe ntchito pamwamba pa valve.

(2) Kupanikizika kotsalira kogwira ntchito kozizira kumatha kuthetsedwa ndi njira zoyenera, monga kupumula kupsinjika pambuyo popindika.

Nthawi yotumiza: Sep-23-2022