1. Zovuta mu Njira ya Msonkhano wa Valve Core

Mu phunziro ili, pambuyo potengera luso la mapangidwe a makina ena odzipangira okha, makina opangira ma semi-automatic omwe analipo adawunikidwa, ndipo gawo lamakina la dongosololi lidapangidwa kwathunthu kutengera kayesedwe kake.valavu coremsonkhano ndondomeko. Mu dongosolo la kamangidwe ka dongosolo, timayesetsa kuti kukonza kwa mbali zamakina kukhala kosavuta, kuchepetsa mtengo, kupanga gulu la magawo kukhala losavuta komanso losavuta, ndikupanga dongosolo kukhala lotseguka komanso lokulitsa, kuti lipititse patsogolo kudalirika komanso kudalirika kwadongosolo. , ndikuyala maziko abwino owongolera mtengo wadongosolo.

Thevalavupachimakedongosolo msonkhano makamaka anawagawa m'magawo atatu mwa mawu ake mawotchi kapangidwe kamangidwe, ndicho: zigawo ziwiri msonkhano pa chapamwamba kumanzere ngodya workbench, atatu msonkhano mbali pa ngodya m'munsi kumanzere ndi zisanu ndi ziwiri msonkhano mbali kumanja kwa workbench gawo. Vuto laukadaulo la msonkhano wamagulu awiri limakhala momwe mungatsimikizire mawonekedwe ozungulira a mphete yosindikiza. Panthawi yodula, idzagonjetsedwa ndi mphamvu ya axial extrusion ya tsamba, kotero zimakhala zosavuta kupunduka . Kachiwiri, pa msonkhano ndondomeko pamene cored ndodo wapezeka pa kutengerapo tooling chigawo chimodzi, m'pofunika kuzindikira kuwunika ndi msonkhano pakati pa zigawo zosiyanasiyana za pachitseko pachimake kudzera kugwedera. Chifukwa chake, gawo lililonse limagwera pamalo ofananirako kuti likhale ulalo wa msonkhano. Vuto la ndondomekoyi liri. Mavuto omwe ali pamwambawa ndi omwe amachititsa kuti chiwerengero cha mankhwala osokoneza bongo chiwonjezeke pa msonkhano wa valavu panthawiyi. Kutengera izi, pepalali limakwaniritsa njira yophatikizira ma valve core, ndikuwonjezera njira yowunikira kuti ipititse patsogolo kuyenerera kwa msonkhano wapakati wa valve.

2. Intelligent Valve Core Assembly Scheme

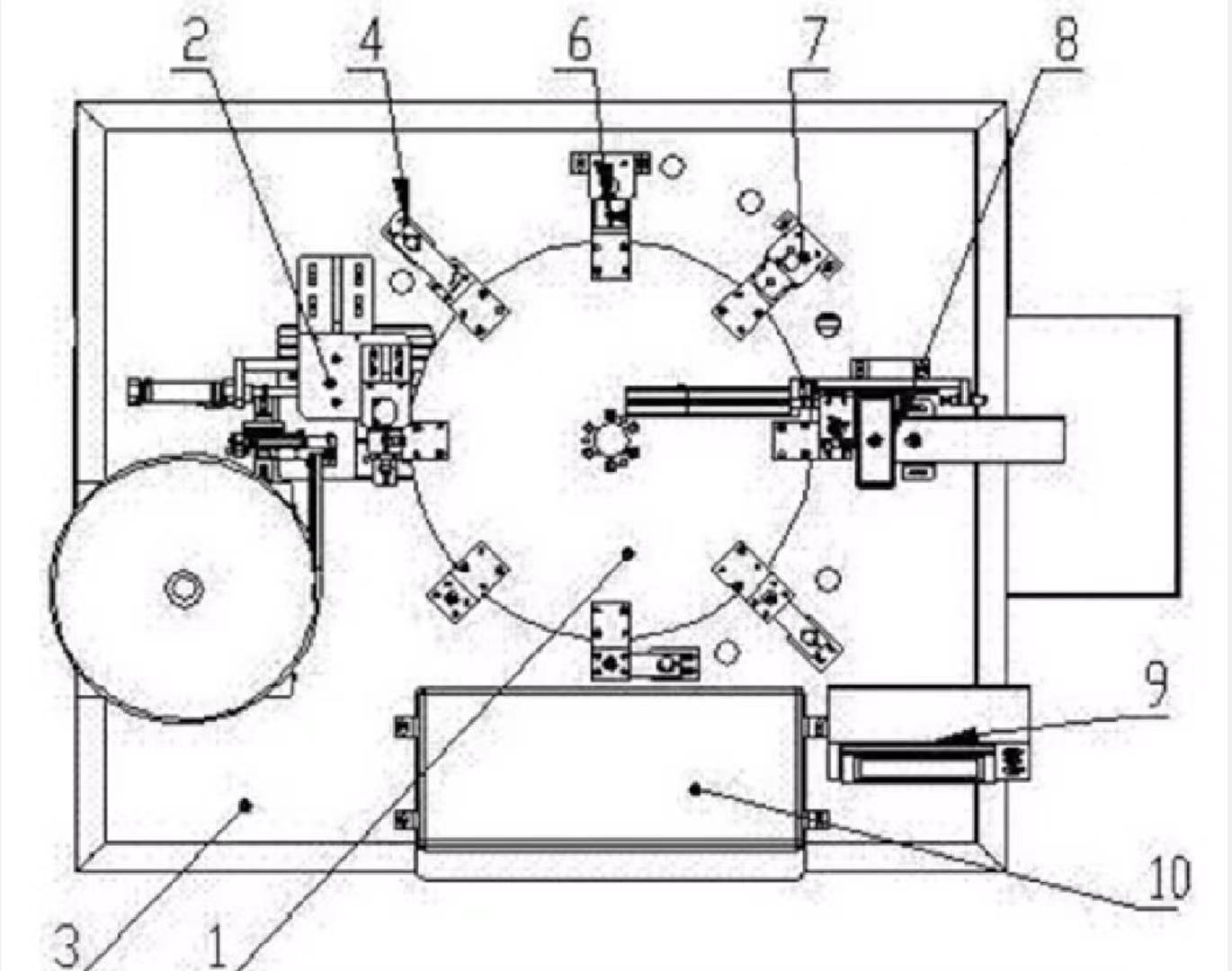

Mawonekedwe ogwirira ntchito ndi PLC amapanga gawo lowongolera malingaliro, ndipo njira yodziwikiratu ndi PLC imakhala ndi njira ziwiri zoyendetsera zidziwitso zosonkhanitsira zidziwitso za dongosolo la msonkhano ndikutulutsa chizindikiro chowongolera. Monga gawo lalikulu, makina oyendetsa amayendetsedwa mwachindunji ndi gawo la PLC. Kupatula njira yodyera, yomwe imafuna thandizo lamanja, njira zina m'dongosolo lino zazindikira msonkhano wanzeru. Kuyanjana kwabwino kwa makompyuta ndi anthu kumatheka kudzera pa touchscreen. Poganizira za kuphweka kwa ntchito pamapangidwe amakina, bokosi loyika pachitseko lili moyandikana ndi chophimba chokhudza. Njira yodziwira, chigawo chapakati pa chitseko chotsegulira pamwamba, chigawo chodziwira kutalika kwa ma valve ndi makina osatsegula amakonzedwa motsatira mbali ya turntable tooling, pozindikira momwe mzere wa msonkhano umapanga msonkhano wapakati pa khomo. Njira yodziwira makamaka imamaliza kuzindikira kwa ndodo, kuzindikira kutalika kwa unsembe, kuyang'anira khalidwe, ndi zina zotero, zomwe sizimangodziwa zokhazokha za kusankha kwa zinthu ndi lock lock lock, komanso zimatsimikizira kukhazikika ndi kukhazikika kwa kayendetsedwe ka msonkhano. Kapangidwe kagawo kalikonse kachitidwe kameneka kakuwonetsedwa mu Chithunzi 1.

Monga momwe tawonetsera m'chithunzichi, turntable ndi cholumikizira chapakati cha ndondomeko yonse, ndipo kusonkhana kwapakati pa valve kumatsirizidwa ndi kuyendetsa kwa turntable. Pamene njira yachiwiri yodziwira imazindikira kuti chigawocho chiyenera kusonkhanitsidwa, chimatumiza chizindikiro ku dongosolo lolamulira, ndipo dongosolo lolamulira limagwirizanitsa ntchito ya gawo lililonse la ndondomeko. Choyamba, chimbale chogwedeza chimagwedeza pachitseko ndikuchitsekera pakamwa pa valve yolowera. Njira yoyamba yodziwira idzawonetsa mwachindunji ma valve omwe sanakhazikitsidwe bwino ngati zipangizo zoipa. Gawo 6 limazindikira ngati mpweya wabwino wa valavu uli woyenerera, ndipo chigawo cha 7 chimawona ngati kutalika kwa chigawo cha valve kukugwirizana ndi muyezo. Zogulitsa zokha zomwe zili zoyenerera pamalumikizidwe atatu omwe ali pamwambawa ndi omwe adzalandidwe mubokosi labwino lazinthu, apo ayi adzatengedwa ngati zinthu zopanda pake.

Msonkhano wanzeru wavalavu corendizovuta zaukadaulo zamapangidwe adongosolo. Pamapangidwe awa, mapangidwe a silinda atatu amatengedwa. Silinda ya slide imayang'anira kutulutsa kuti zitsimikizire kuti ndizosiyana ndi zotulutsa; silinda yachiwiri imatsimikizira kuti ndodo ya loko ikugwirizana ndi dzenje lotulutsa, ndiyeno imagwirizana ndi slide slide kuti amalize valavu yopita ku ndodo ya loko, ndiyeno Silinda yachiwiri ikupitiriza kukankhira njira yonse yotsekera kuti isunthe, ndipo mphuno yoyamwa idzayamwa valavu ikafika pansi pa tooling. Pomaliza, silinda yachitatu ikakankhira njira yotsekera m'malo, injini ya servo imatumiza pachimake cha valve kukamwa kwa vavu kuti amalize kuyika pachimake cha valve. Njirayi imatsimikizira kulondola komanso kusiyanasiyana kwa malo oyenda nthawi yayitali komanso ofananira nawo, ndipo imapereka njira yabwino yothetsera zovuta zaukadaulo za msonkhano wapakhomo..

3. Mapangidwe a Zigawo Zofunikira za Valve Core Assembly System

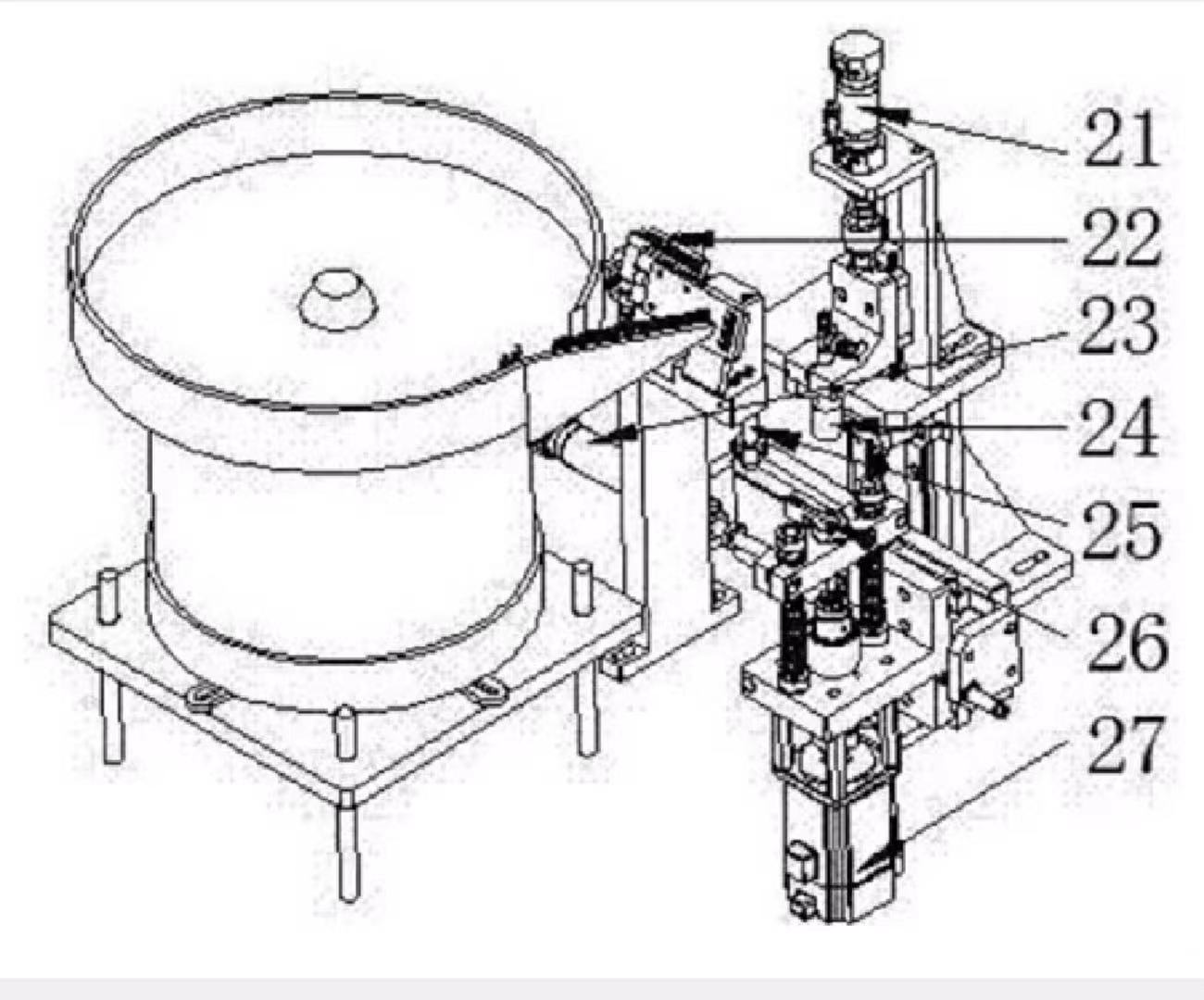

Monga njira kiyi khazikitsa ndivalavu corepa valavu, kutseka pachimake cha valve kumakhala ndi zofunikira kwambiri pa kulondola kwa kayendetsedwe ka kayendetsedwe ka valve core, kotero kumafunika kugwirizana kwa njira zotalika ndi zam'mbali kuti zitheke. M'mapangidwe a gawoli, amawonongeka kukhala chinthu chimodzi, kutulutsa kwa valve pachimake, kutsekera kwa lever yotsekera komanso kuchitapo kanthu pokweza phokoso la valve pamphuno ya valve. Mapangidwe ake amakina akuwonetsedwa mu Chithunzi 2. Monga momwe tawonera pa Chithunzi 2, makina opangira ma valve core msonkhano amagawidwa m'magawo atatu. Zigawo zitatuzi zimagwira ntchito mogwirizana popanda kukhudzana. Ntchito yodziyimira payokha ikamalizidwa, silindayo imakankhira makinawo kuti asunthire kumalo a msonkhano wotsatira.

Pofuna kutsimikizira kulondola kwa malo osuntha, mapangidwe athunthu a kayendetsedwe ka magetsi ndi malire a makina amatengedwa kuti athetse vutolo mkati mwa 1.4mm. Pakatikati pa valavu ndi pakatikati pa nozzle ya valve ndi coaxial, kotero kuti servo motor imatha kukankhira pachimake valavu mumphuno ya valavu bwino, apo ayi zitha kuwononga magawowo. Kuyimitsidwa kwa kapangidwe ka makina kapena kugunda kwamphamvu kwa ma siginecha amagetsi kungayambitse kupatuka pang'ono pantchito yolumikizira. Chotsatira chake, chikasonkhanitsidwa pachimake cha valve, ntchito ya mpweya wabwino siikwanira, ndipo kutalika kwa msonkhano sikuli koyenera, zomwe zimapangitsa kuti mankhwalawa alephereke. Izi zimaganiziridwa bwino pamapangidwe adongosolo, kuzindikira kuphulika kwa mpweya ndi kuzindikira kutalika kumagwiritsidwa ntchito posankha zinthu zoyipa.

Nthawi yotumiza: Sep-09-2022